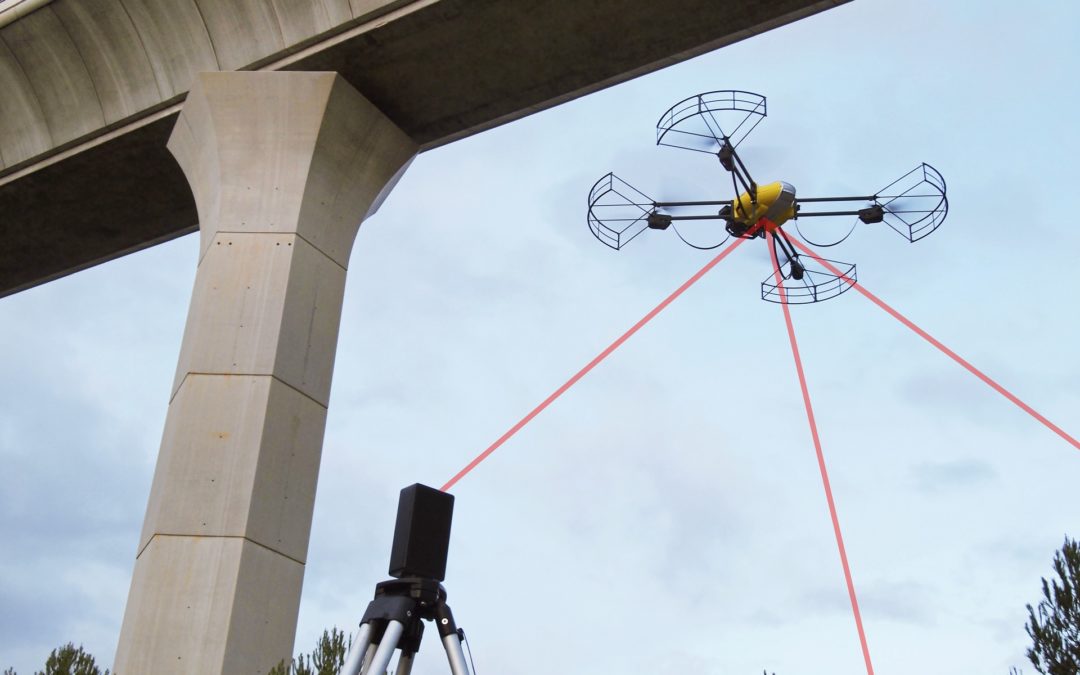

The LPS technology of Novadem (Local Positioning System) allows for the first time to perform fully automatic inspection of structures. Based on its own terrestrial beacons network, the LPS technology reaches a centimeter-level accuracy while being independant from the satellite coverage.

Novadem, manufacturer of micro-UAVs for civil and military applications since 2006, is the french leader of UAVs intended for structures’ inspection. Among its customers are major players in the field of inspection such as SPIE Batignolles Technologies, EGIS or SETEC DIADES.

« Some of our customers have been using the U130 micro-UAV for more than five years. Consequently we have acquired an in-depth knowledge of the needs linked to the use of UAVs for complex structures’ inspections », explains Pascal Zunino, Director of Novadem.

Some of these needs include the precise positioning of the UAV close to and even under structures. Indeed, in these conditions, the GPS cannot get measures because of the lack of satellites in view. Operators have no other choices but to perform these inspections in manual piloting mode, making it difficult and even dangerous. Moreover, the analysis of pictures to find and locate the structures’ defects is long and tedious. To face this challenge, Novadem has developed during two years the technology called LPS.

The Novadem LPS technology is close to the GPS technology but instead of using satellites, it uses terrestrial beacons which create a local positioning network under the structure. This network can easily be extended by adding beacons, each of them covering a 200 meters radius area. As a result, the solution is fully independant from the satellite coverage with unreached capacities so far :

– A positioning precision of 10 centimeters in the three dimensions.

– A fast acquisition with 25 measures per second.

– A constant quality of measurement and constant signal availability.

– A position measurement independant from the evolution area (brightness, type of surface, etc.).

– A user-specified origin of measurement.

These performances give new perspectives to inspections performed by UAVs thanks to flights that can be 100% automated even under structures. It is now possible to ensure the repeatability of the inspection over time. As a result, the security and efficiency of missions is significantly increased compared to a manual piloting. Add to that a more precise georeferencing of pictures allowing to optimise the flight plan on the areas to inspect and to rationalise the volume of data, thus simplifying the processing.

With the LPS technology, Novadem allows for a breakthrough in the field of inspection by allowing the automatisation of flights and the georeferencing of data in environments without GPS coverage. Difficult inspections will no longer be reserved to experts in piloting but accessible to all. The use of the LPS technology can satisfy indoor (buildings, tunnels,…) and outdoor inspections (wind turbines, high-tension pylons, etc.). The LPS technology will be soon experimented with big players of the sector and will be

commercialy available in the course of 2015.