A passion, A story

It all started in 2005, when Pascal Zunino, just graduated from the National Polytechnic Institute of Grenoble (INPG), won with his team of engineers the first prize at the international contest of aerial robotics organized by the DGA and ONERA (2005 Micro-drone Contest, team CPX4). They had designed the first folding quad-rotor micro-drone of less than one kilogram, the CPX4, which was then evaluated on the Mourmelon military camp. Over the following months, several manufacturers, convinced by his project, proposed him to integrate their structures to continue his work. Witnessing the interest aroused by his vision of aerial robotics, Pascal Zunino, senses the multiple contribution of micro-drones in public safety, private security and the defense sectors (in 2005, drones were mainly used in the field of defense and weighed several tens of kilos). Convinced, he set up Novadem in 2006 (« Nova » for innovative and « dem » for electronic and mechanical development) with his childhood friend, Fabien Paganucci and his brother Eric Zunino.

The complementary skills of the three founders, Pascal in the field of on-board electronics and signal processing, Fabien in micro-mechanics and Eric in computing, will allow to start the development of a range of drones designed to meet the needs of industry, defense and security professionals.

More than 10 years later, Novadem has become one of the leaders in its sector. Its drone solutions have convinced many major customers in France and abroad : Defense (Directorate General for Armament, Technical Section of the French Army, French Navy, etc.), Public Safety (firefighters : SDIS 13, French General Directorate for Civil Protection and Crisis Management (DGSCGC), etc.), Gendarmerie / Police Force (French National Gendarmerie, Police of Brussels, Police of the Canton of Vaud (Switzerland), etc.), Industry (French electricity company, SPIE Batignolles, SETEC, EGIS, etc.).

From left to right : Fabien PAGANUCCI, Eric ZUNINO, Pascal ZUNINO

Novadem in figures :

Years of customer feedbacks

Millions of funded collaborative projects

European tenders won

Drones manufactured

Prizes and honors

French and foreign States Services equipped

A vision, A vocation

« In 2006, when we decided to set up Novadem, we followed a vision : tomorrow the aerial dimension will be accessible to professionals from industry, security and defense to facilitate their daily missions. We started from scratch and designed our own drones solutions alongside our customers with a clear objective in mind : provide them with a powerful, simple and intuitive tool.

Recreational drones are used to produce illustrative pictures or video footages, but Novadem’s customers need to go one step further. For companies specialized in structure inspection, the image is only an input that is valuable if it brings added value during the expertise phase allowing to follow the evolution of the structure defects over time. For the firefighter, the image brings value only if it is shared in real time with the command post thereby enabling a better understanding of the situation and its evolution and optimizing ground crews’ coordination. For the soldier, the image must be combined with maps compatible with defense standards and incorporate a digital terrain model to display precise GPS coordinates essential for sending teams to the area of interest.

Novadem is proud to be the French pioneer of professional micro-drones and one of the few players in the world to benefit from more than 10 years of feedback on the use of its solutions. »

Pascal Zunino – Co-founder and CEO of Novadem

Novadem, the story of a pioneer

Experience gained over the years and innovations

The INPGrenoble CPX4 engineering team led by Pascal Zunino wins the first prize at the International University Contest about mini-UAVs organized by the ONERA and DGA. The use of a U130 UAV to inspect a nuclear reactor is a world first achieved by Novadem in A1 and A2 Chinon reactors. As part of the PHOENIX II program, the Novadem team worked to develop a data link between the NX110M and the FELIN messaging. The highest viaduct in the world (Millau - 343 m) was inspected by a U130 drone. This world first still represents a benchmark in the inspection of high viaducts. The S.D.I.S.13 firefighters acquire a NX110 and thus become one of the first French units to exploit this new technology. Novadem's Local Positioning System (LPS) enabled a world first for a fully automated structure inspection without GPS. After a European tender procedure, Novadem delivers a fleet of NX110 to the French Gendarmerie Nationale. Novadem wins with the drone NX70, the second tender of the French National Gendarmerie on the purchase of 19 UAVs. More than 50 NX70 micro-drone have been ordered by the French Defense Procurement Agency (DGA) to equip soldiers deployed in external operations. Following an international market research, MBDA has selected the NX70 to expand the capabilities of its next-generation land-based missile, the MMP. Less than a year after having projected the first NX70 micro-drones in external operations, the DGA (French Defense Procurement Agency) placed a new order with Novadem to double its fleet. A fleet of NX70 micro-UAVs has been acquired by the Marseille’s Navy Firefigters Battalion (BMPM) to support operations. September 2005

TEAM CPX4 WINS ONERA / DGA MINIDRONE CONTEST

September 2010

THE U130 INSPECTS CHINON NUCLEAR REACTOR

June 2011

NX110M INTEGRATED INTO THE FELIN MESSAGING

October 2011

FIRST INSPECTION OF MILLAU VIADUCT BY A U130

July 2014

THE S.D.I.S.13, FORERUNNER IN THE USE OF DRONES

December 2014

FIRST AUTOMATIC INSPECTION BY DRONE WITHOUT GPS

October 2015

1ST AWARD WITH THE FRENCH NATIONAL GENDARMERIE

November 2016

SECOND TENDER FOR FRENCH NATIONAL GENDARMERIE WON

December 2018

THE FRENCH MINISTRY OF DEFENSE CHOOSES THE NX70

April 2019

THE NX70 EXTENDS MBDA'S MMP CAPABILITIES

December 2019

THE FRENCH MINISTRY OF DEFENSE DOUBLES THE NUMBER OF NX70 DEPLOYED

Jun 2020

THE MARSEILLE'S NAVY FIREFIGHTERS BATTALION ACQUIRES NX70 DRONES

We changed their jobs

More than 13 years of innovation to serve the most demanding professionals

A unique technological expertise

Thanks to its strong technological complementarity (Mechanics / Electronics / Computing / Ergonomics), Novadem guarantees a comprehensive technical and industrial mastery, from design to manufacturing. Since 2006, Novadem has used its skills to develop its own products in the field of aerial robotics (UAV/drone). Its know-how in engineering is now both recognized by most manufacturers in the field and high-tech SMEs who call upon Novadem expertise.

MECHANICS

|

Novadem fully develops all the mechanics of its systems. With a complete control of the conception process and industrialization Design : CAD, propeller development, composite structure. Prototyping : Composite production, thermoforming, additive production, conventional and digital machining. Production : Industrial file, assembly, methods.

|

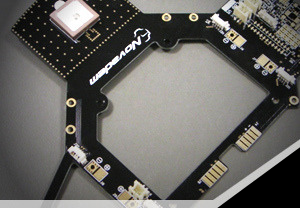

ELECTRONICS

|

Novadem fully develops all the electronics of its systems. Its expertise in terms of embedded electronics ensures a perfect control of every key function quality and performances : Inertial unit / Engine controller / Video management / Charger / Battery management. Design and routing : Schematic and PCB design, EMC study and thermal. Signal processing : Digital filtering, optimal control, sensor pre-processing. Radio Frequency : Pre-qualification tests, antenna impedance adaptation, EMC measurements. |

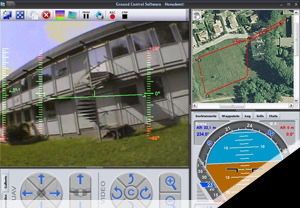

COMPUTING

|

The software is fully developed by Novadem. Thus, Novadem offers its customers a unique adaptability to enrich the system according to customer expectations (specific export data format, business functions, information sharing, etc.). Real-time systems : Micro-controller / DSP programming, embedded OS. Cartography : Geographic Information Systems (GIS), multi-formats management, digital terrain model (DTM DTED). Video : Image compression, streaming, real-time image processing. |

ERGONOMICS

|

Novadem has a strong experience in systems ergonomics, both on software with the design of specialised Human-Machine Interfaces and on products with a design approach oriented on usage and mobility. Software : tactile human-machine interface, simulation tools to improve interfaces. Products : physical prototypes, usage and mobility studies.

|

MECHANICS

Novadem fully develops all the mechanics of its systems. With a complete control of the conception process and industrialization

Design : CAD, propeller development, composite structure.

Prototyping : Composite production, thermoforming, additive production, conventional and digital machining.

Production : Industrial file, assembly, methods.

ELECTRONICS

Novadem fully develops all the electronics of its systems. Its expertise in terms of embedded electronics ensures a perfect control of every key function quality and performances : Inertial unit / Engine controller / Video management / Charger / Battery management.

Design and routing : Schematic and PCB design, EMC study and thermal.

Signal processing : Digital filtering, optimal control, sensor pre-processing.

Radio Frequency : Pre-qualification tests, antenna impedance adaptation, EMC measurements.

COMPUTING

The software is fully developed by Novadem. Thus, Novadem offers its customers a unique adaptability to enrich the system according to customer expectations (specific export data format, business functions, information sharing, etc.).

Real-time systems : Micro-controller / DSP programming, embedded OS.

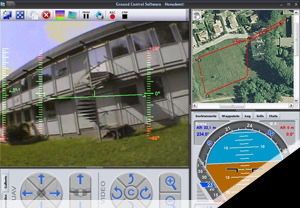

Cartography : Geographic Information Systems (GIS), multi-formats management, digital terrain model (DTM DTED).

Video : Image compression, streaming, real-time image processing.

ERGONOMICS

Novadem has a strong experience in systems ergonomics, both on software with the design of specialised Human-Machine Interfaces and on products with a design approach oriented on usage and mobility.

Software : tactile human-machine interface, simulation tools to improve interfaces.

Products : physical prototypes, usage and mobility studies.

Novadem, a pioneer for which innovation is part of its DNA

The Novadem team innovates every day to propose its customers the highest technology level. Our goal is to increase systems’ operational added value : for example, since 2009, Novadem had developed a tethered solution, thus allowing the drone to fly unlimited for missions requiring observation persistence. More recently, our latest generation of NX70 drone solution allows to go beyond the vision and to move into action thanks to its carrying capacity which allows it to drop different types of devices : kevlar to pull a zip line between two cliffs or to quickly access the victim.

By calling up upon Novadem skills in ambitious R&D projects, SMEs and large industrial groups demonstrate their confidence in our technological expertise. Over the years, Novadem had worked alongside companies such as Airbus Defence & Space, MBDA, SAFRAN, CNRS, CEA, Nexvision, Inpixal, Delair or INRA through collaborative projects whose results already foreshadow what tomorrow’s drones will be.

![]()

They support us

Since the beginning of the adventure, we have found the support of different partners which has allow us to continuously develop our solutions in the best conditions :